Hydro Cooling

Advantages of Hydro Cooling:

Hydro cooling is a postharvest cooling method where fruits and vegetables are rapidly cooled by immersion in or spraying with cold water.

- Rapid Cooling

- Water has a much higher heat transfer rate than air, so hydrocooling removes field heat quickly.

- This helps maintain freshness and slows down respiration and ripening.

- Reduces Moisture Loss

- Unlike air cooling, hydrocooling prevents dehydration because the produce is in contact with water.

- This helps maintain weight and crispness.

- Improves Shelf Life

- Rapid temperature reduction slows microbial growth and enzymatic activity.

- Extends storage and market life significantly.

- Energy Effciency

- Water is an efficient cooling medium, often requiring less energy compared to forced-air cooling for the same temperature drop.

- Uniform Cooling

- Water surrounds the produce, ensuring even cooling regardless of shape or size.

- Compatible with Many Crops

- Works well for dense or bulky produce like melons, sweet corn. carrots, broccoli, cherries and many other fruit & Vegetable types.

Limitations to keep in mind:

- Not suitable for produce sensitive to water (e.g., berries, mushrooms).

- Requires clean, sanitized water to avoid contamination.

- Initial setup cost can be high.

Hydro Cooling Product Range

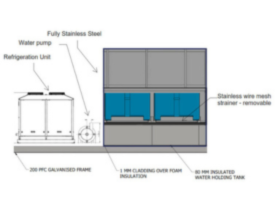

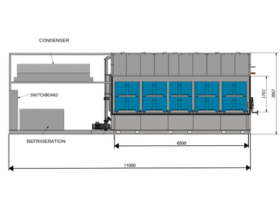

MODEL: HC-2 Bin

CAPACITY:

INTERNAL DIMENSIONS:1100mm x 1300mm x 2650mm high

POWER REQUIRMENTS:415 Volts 3 Phase 80 Amps

COOLING TIME:20 – 45 minutes depending on produce

MODEL: HC-4 Bin

CAPACITY:

INTERNAL DIMENSIONS: 1100mm x 1300mm x 2650mm high

POWER REQUIRMENTS: 415 Volts 3 Phase 80 Amps

COOLING TIME: 20 – 45 minutes depending on produce

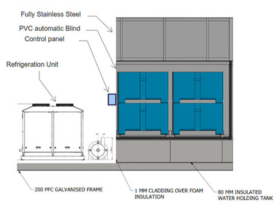

MODEL: HC-6 Bin

CAPACITY: 2 PALLETS

INTERNAL DIMENSIONS: 1100mm x 1300mm x 2650mm high

POWER REQUIRMENTS: 415 Volts 3 Phase 80 Amps

COOLING TIME: 20 – 45 minutes depending on produce

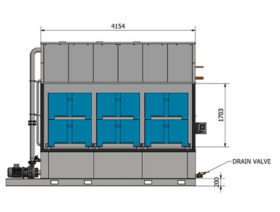

MODEL: HC-8 Bin

CAPACITY: 2 PALLETS

INTERNAL DIMENSIONS: 1100mm x 1300mm x 2650mm high

POWER REQUIRMENTS: 415 Volts 3 Phase 80 Amps

COOLING TIME: 20 – 45 minutes depending on produce

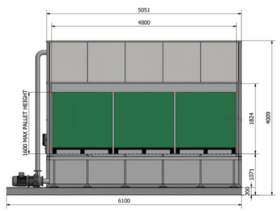

MODEL: HC-10 Bin

CAPACITY: 2 PALLETS

INTERNAL DIMENSIONS: 1100mm x 1300mm x 2650mm high

POWER REQUIRMENTS: 415 Volts 3 Phase 80 Amps

COOLING TIME: 20 – 45 minutes depending on produce

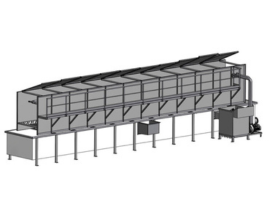

MODEL: HC-10 Thr

CAPACITY: 10 Ton per hour

INTERNAL DIMENSIONS: 1200mm wide x 15000 long

POWER REQUIRMENTS: 415 Volts 3 Phase TBA Amps

COOLING TIME:20 – 60 minutes depending on produce